Polyurethane screens

Polyurethane screens

Maximum durability for wet and dry screening

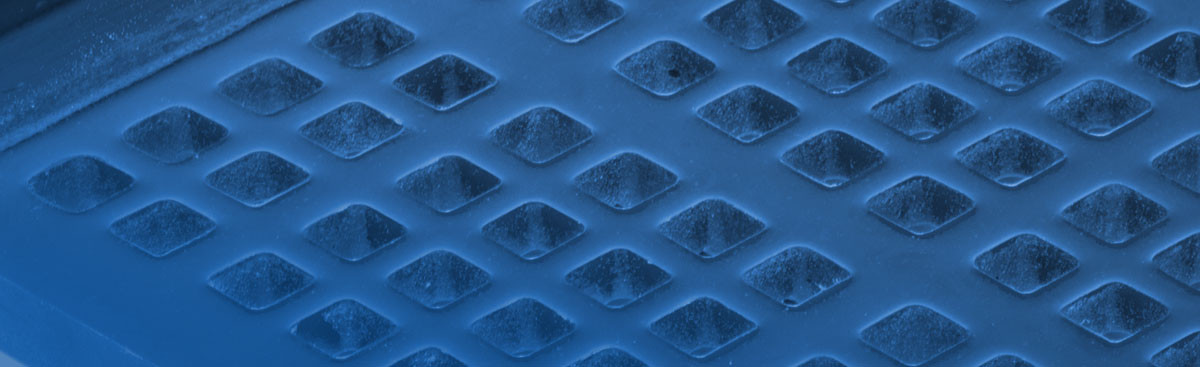

Polyurethane screens are an ideal substitute for wire screens for screening dry and wet materials when it allows a sufficient size of the screen area. They are characterized by several times longer lifetime and resistance to mesh blocking.

- Extreme durability for wet and dry screening

- Suitable as landing or complete screening areas

- In the case of the modular system, wide variability and the possibility to adjust the screen surface in a short time

POLYURETHANE TENSIONED SCREENS

Polyurethane tensioned screens are used for screening abrasive materials that tend to clog screens. They are made of anti-abrasive materials in hardness from 55 to 90 Shore, depending on the material to be screened. Their reinforcement consists of steel ropes and transverse steel reinforcement which are supporting elements in the construction of these screens. They are suitable as a direct replacement of metal screens with a fold without any additional adjustments of the screening machine.

Polyurethane screens are cast in one unit with tensioning folds designated for longitudinal and transverse clamping on the screening machine.

- Several times longer lifetime compared to metal screens

- Can be used in combination with wire screens on one screen surface without interfering with the screening machine construction

- Can be supplied with holes for mounting the central pressure bar

MESH SIZE

2.5 - 200 mm (square or rectangular mesh)

SCREEN THICKNESS

20 - 60 mm

MATERIAL

Polyurethane elastomer type A in the range of 55 - 90 Shore Inside armed with a steel reinforcement.

DIMENSIONS

Maximum fold width: 1500 mm

Maximum screen width (Spi/Spa) between the folds: 3000 mm

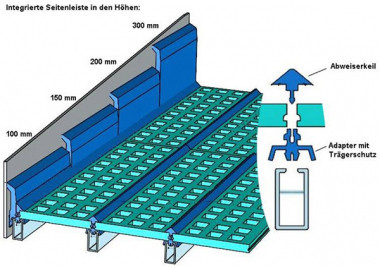

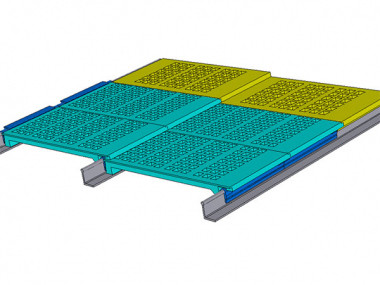

CLIP-TEC CONSTRUCTION SYSTEM

Clip-Tec is the most optimal way of full mounting of the screen surfaces on a screening machine of a standard construction, where the screen modules are fixed on special beams. These enable quick replacement of individual modules that can be changed and exchanged with each other. These modules have a standard size of 300 x 1000 mm and a weight of up to 10 kg, requiring much less maintenance as well as overall handling.

In the case of screen wear, it is not necessary to replace the entire tensioned area of a size of e.g. 2 m2, but only a module with a size of 0.3 m2, which results in significant financial and time savings.

The big advantage of this system is also the possibility to use wide range of accessories to this system, such as wire adapters that allow the installation of wire screens, up to various retarders, deflectors and other accessories that affect the overall quality of screening.

- Extreme durability for wet and dry screening

- Great variability of use of various screens as well as accessories

- Reduced maintenance, handling and screen replacement requirements

MESH SIZE

0.3 - 200 mm (square or rectangular mesh)

SCREEN THICKNESS

30 - 60 mm

MATERIAL

Polyurethane elastomer type A in the range of 55 - 90 Shore

(When Draining - thermoplastic liners)

DIMENSIONS

Usually 300 x 1000 mm, possible to customise up to max. dimensions 400 x 1500 mm

ALL-CAST SELF-SUPPORTING AREAS

Polyurethane screens cast in one piece are reinforced with a supporting frame and are fixed depending on the construction of the screening machine either by screws or by a system of side rails and wedges.

MESH SIZE

2.5 - 200 mm (square or rectangular mesh)

SCREEN THICKNESS

20 - 60 mm

MATERIÁL

Polyurethane elastomer type A in hardness range 45 - 90 Shore. Inside armed with a steel reinforcement.

DIMENSIONS

Maximum dimensions: 1500 x 3000 mm