Harp screens

Harp screens

Maximum performance under all conditions

They are a specific type of screens used mainly for screening difficult-to-screen, especially wet and abrasive materials. The construction of the harp sieve is designed in such a way that the longer wires are clamped to each other at a relatively large distance by a transverse bond, which ensures that besides screening machine vibrations, the screen itself produces its own dissonant frequency, which counteracts sticking and clogging of the screen meshes.

Harp screens are supplied exclusively with tensioning folds, which are necessary for the correct operation of the screen. The screens are supplied with wire or polyurethane braids, which further increase the lifetime and efficiency of the screens. When ordering harp nets, we recommend you to choose a mesh size that is 10% smaller than that of wire screen with rectangular meshes.

- Screening of difficult-to-screen materials

- Self-cleaning effect

- High efficiency

FIELD OF APPLICATION

Gravel pits, sand pits, quarries, mines, recycling, asphalt production.

DIMENSIONS SUPPLIED

The screens with tensioning folds are custom-made.

MATERIALS SUPPLIED

Spring steel: STN 12050, DIN 17223

Stainless steel materials: DIN 1.4301, 1.4310

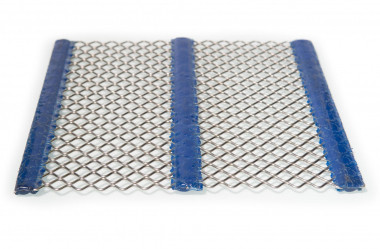

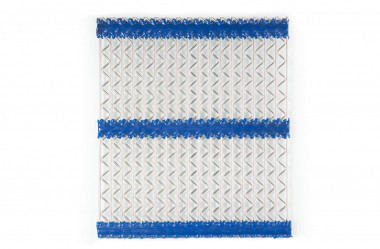

WITH HORIZONTALLY CRIMPED WIRES (SERFESTA)

The basic characteristic of this screen is the horizontal corrugation of the wires which are laid and held side by side in such a way that they form a square mesh shape. They are used for screening dry as well as wet, difficult-to-screen materials with a round, cubic, flat and needle grain shape.

- Direct replacement for square mesh screen without loss of sharpness of screening

-

Suitable for all grain types

- The corrugation of the wires allows relatively accurate screening even with flat and needle-shaped grains.

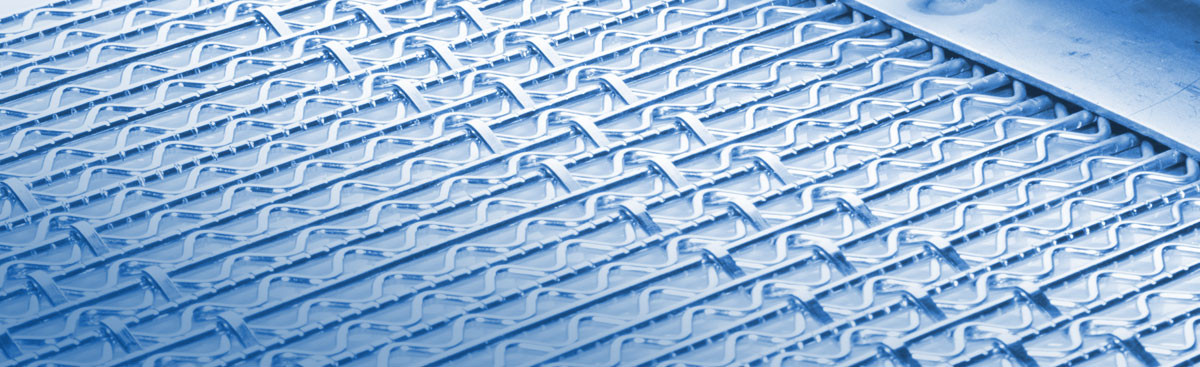

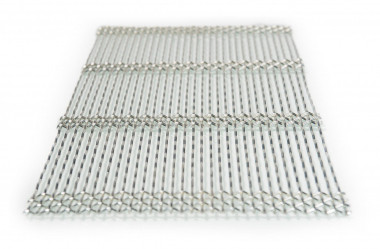

WITH VERTICALLY CRIMPED WIRES (NORMAL)

Harp screen with large open area and high permeability, used for screening wet and difficult-to-screen materials with round or cubic grain shape. Not recommended for flat and needle-shaped material. It consists of vertically crimped wires that are interwoven at certain distance to form a rectangular mesh.

- High efficiency and permeability

- Suitable for screening difficult-to-screen materials

- It is not recommended for screening materials with needle and flat grain shape

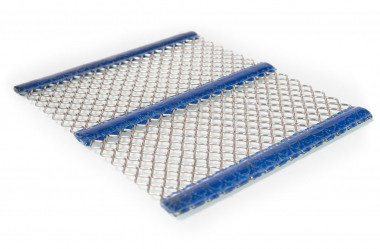

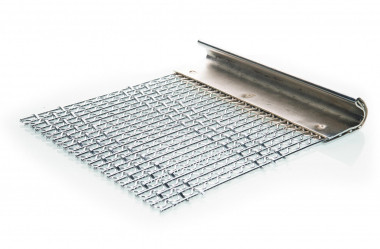

WITH HORIZONTALLY CRIMPED AND STRAIGHT WIRES (DOSER)

Harp screens designated primarily for screening larger volumes of material. It consists of longitudinally horizontally corrugated and straight wires that form triangular mesh. The straight wires take over the tensioning force, while the corrugated wires vibrate and create a self-cleaning effect. This screen design allows for a larger amount of material to be screened. Besides that, unconventional wire bonding maintains a relatively high screening accuracy as well as relatively good performance.

- Suitable for screening larger quantities of material

- The screen construction does not allow overtensioning

- Suitable for all grain types

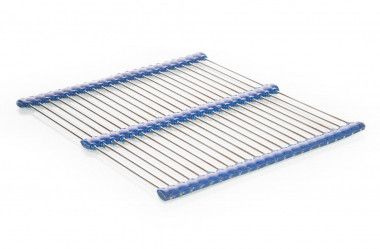

STRING SCREENS WITH STRAIGHT WIRES (CLEAN PURE)

A very permeable type of harp screen suitable especially for screening clay and other difficult-to-screen materials with round or cubic grain shape. It is made up of longitudinal straight wires, which are joined at certain distances by polyurethane. This screen construction is characterized by a high open area and high performance.

- Suitable for screening clay materials

- High performance and open area

- Not recommended for needle and flat grain material