Wire conveyor belts

Wire conveyor belts

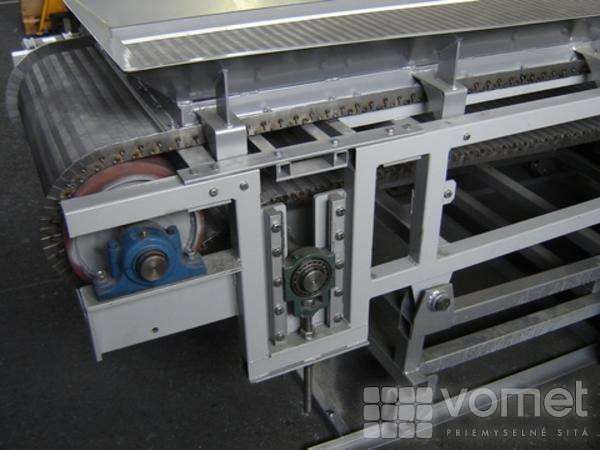

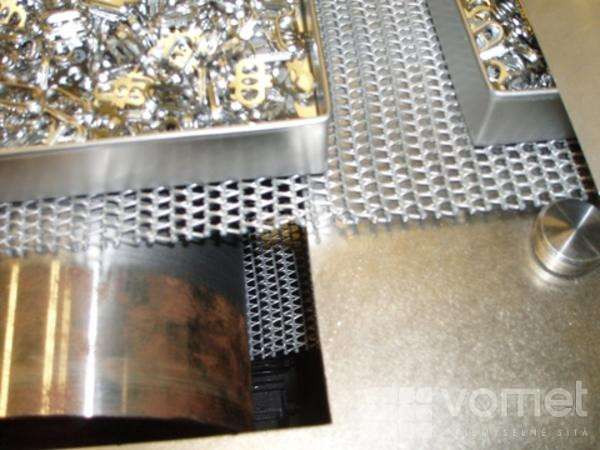

They are used in almost all branches of industry as a means of speeding up transport and handling of products as well as overall efficiency of production. These belts are often already part of production equipment and technological units. These are mainly wire belts, but also hinged steel belts.

USED MATERIALS

The belts are made of various materials according to the purpose of their use. The most common materials for their production are shiny types of steel of common quality, galvanized steel, stainless steel or steel resistant to high temperatures and last, but not the least also acids. As for the metal belts, the range of application is for temperatures from - 200 °C to + 1200 °C.

- Shiny steel (black)

the working temperature does not exceed approx. 350 °C - Galvanized steel

- Galvanized steel

Up to approx. 700 °C. The most commonly used material quality types are DIN 1.4301. - High temperature resistant steel

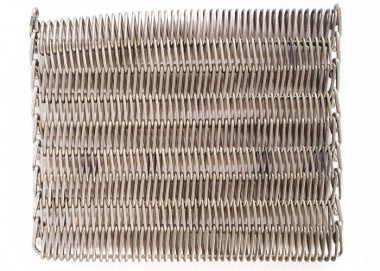

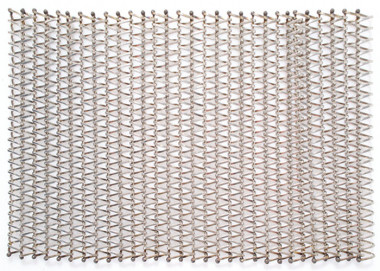

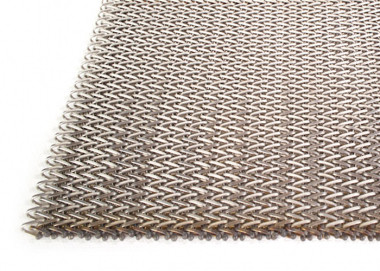

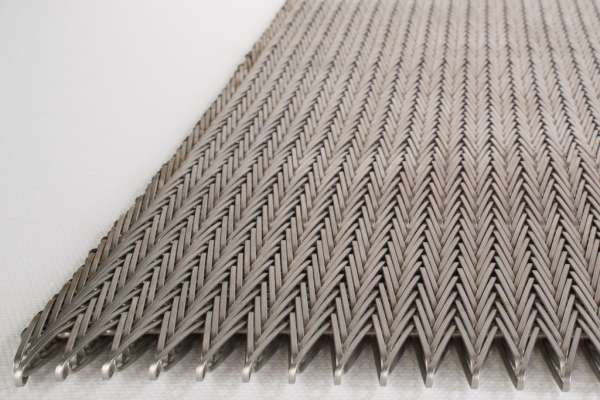

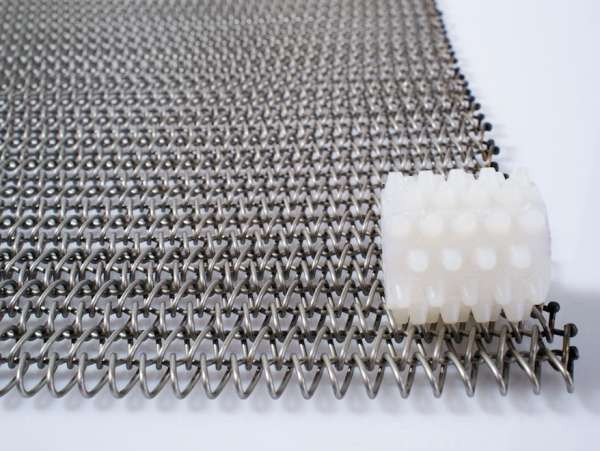

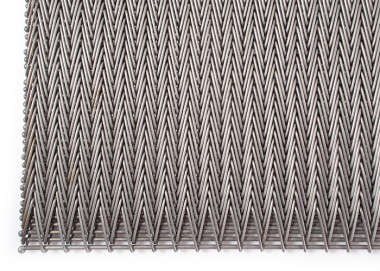

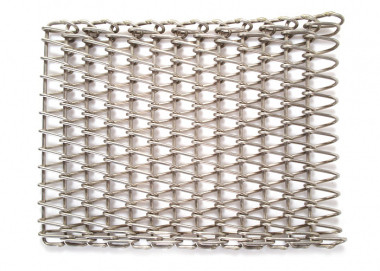

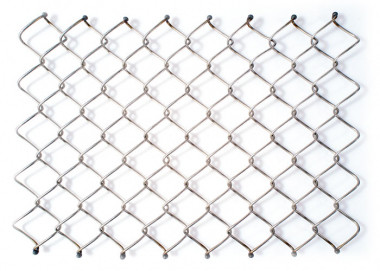

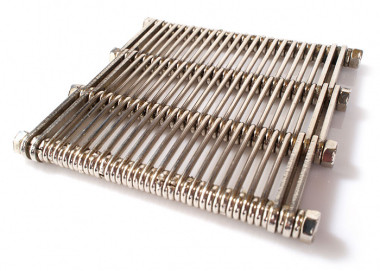

TYPE 100

Description

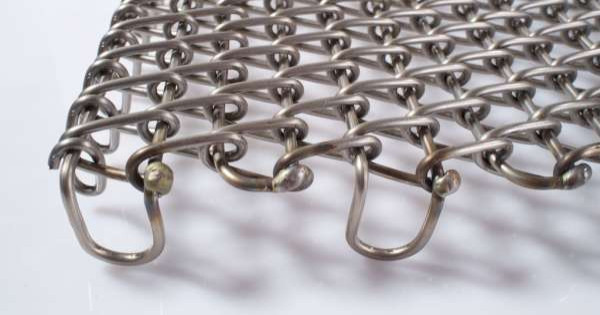

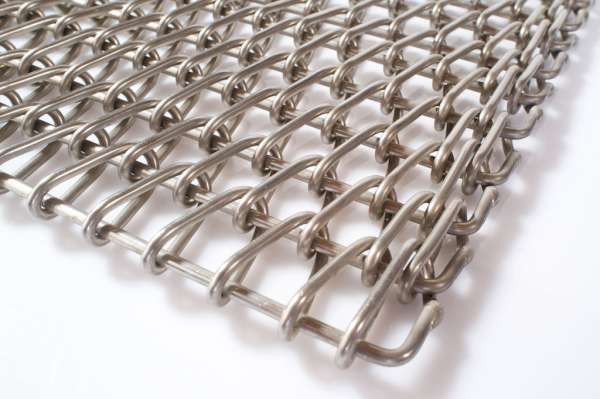

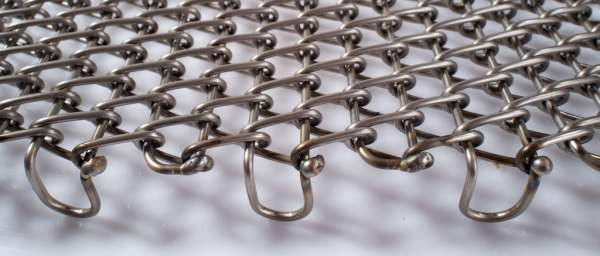

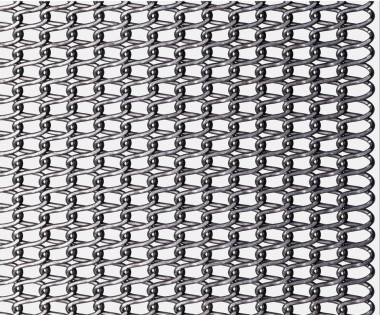

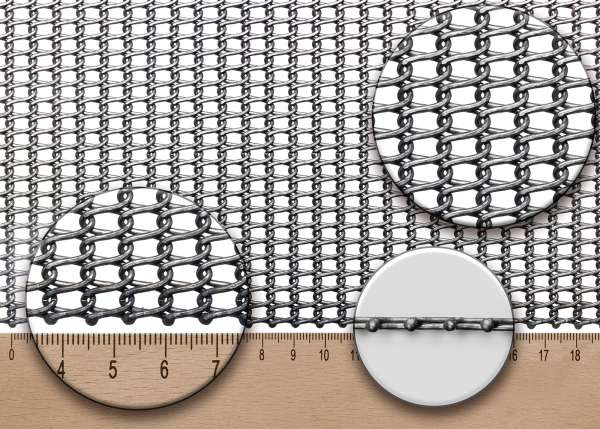

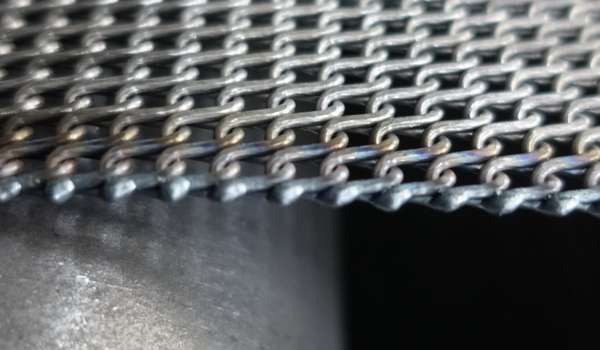

The belt is made of densely woven spiral wires of a flat profile. Alternately left and right woven spirals are connected to each other by perpendicular cross wires. The ends of these cross wires are either finished by a loop or by an inward incurvation of the belt. The third option is that they are welded. The way of their finishing is usually chosen according to the diameter of the cross wires - in the case of thinner wires by a loop or incurvation, in the case of thicker ones by welding.

Use

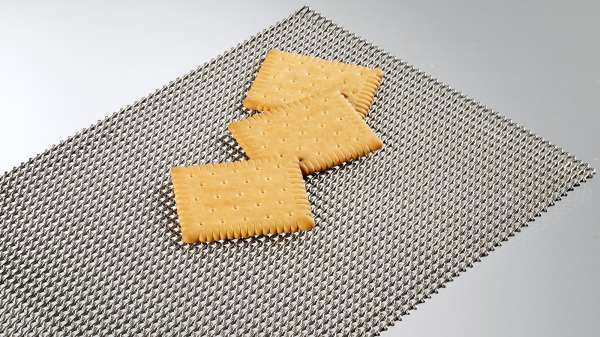

It is used as a cooling belt in the confectionery and chocolate industry, as a conveyor belt in the chemical industry, as a cooling belt for rubber and plastic products, for glass products and hot castings etc.

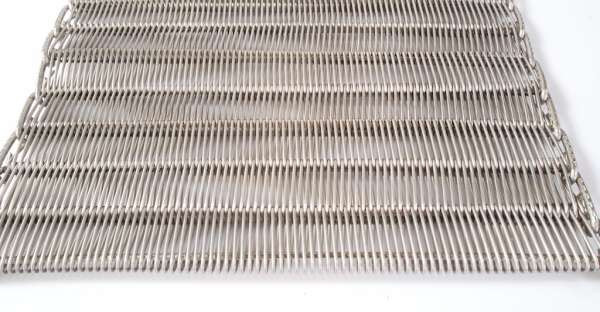

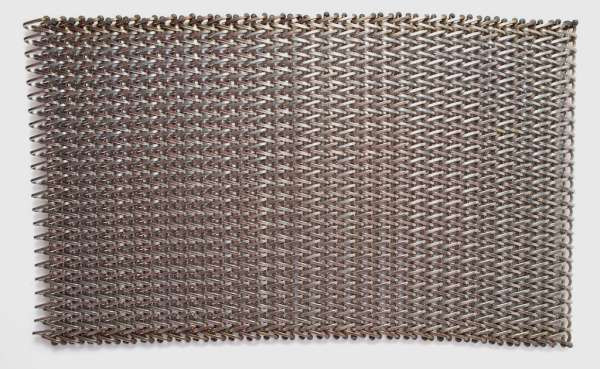

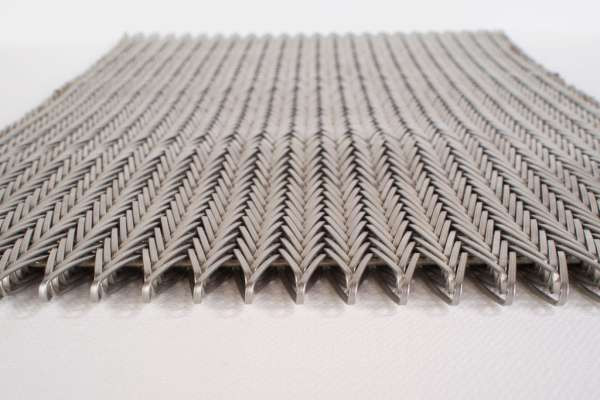

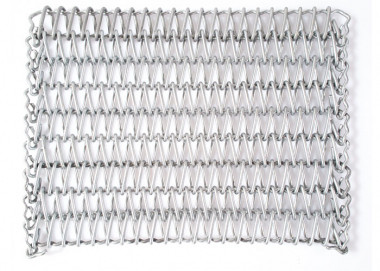

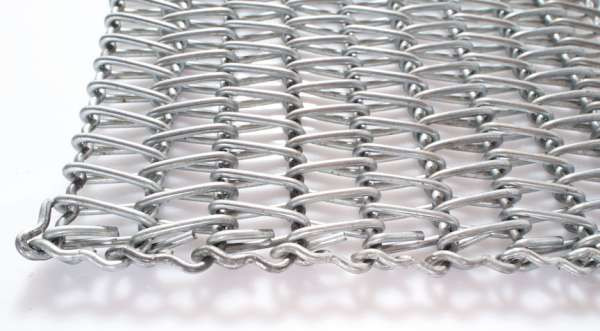

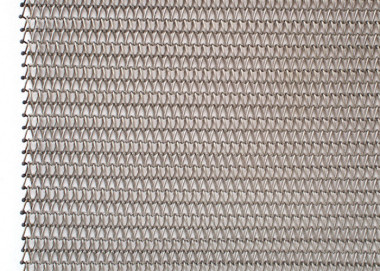

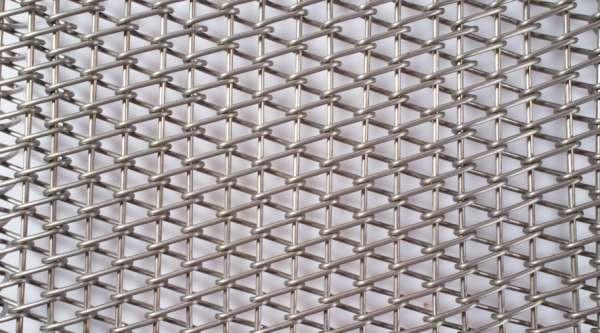

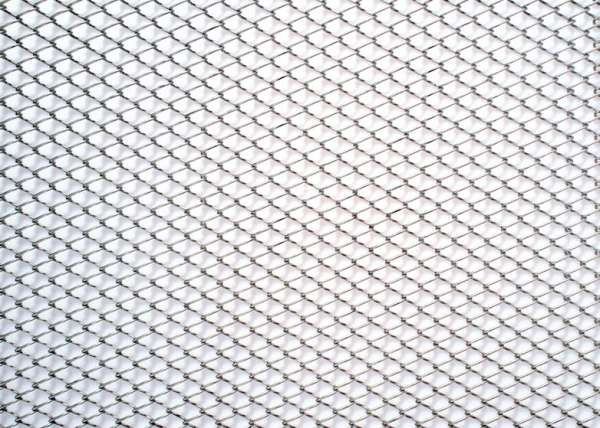

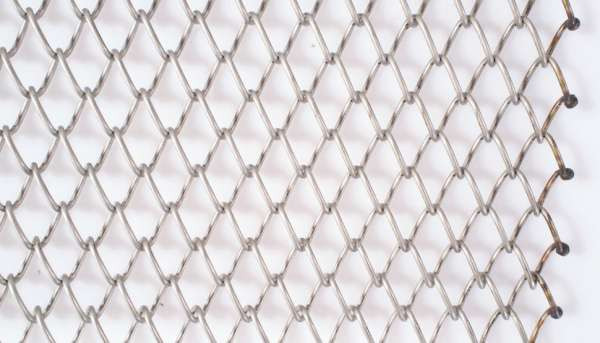

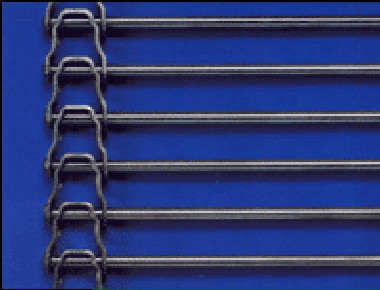

TYPE 200

Description

The belt is made of densely woven spiral wires of a circular profile. Alternately left and right woven spirals are connected to each other by perpendicular cross wires. The ends of these cross wires are either finished by a loop or by an inward incurvation of the belt. The third option is that they are welded. The way of their finishing is usually chosen according to the diameter of the cross wires - in the case of thinner wires by a loop or incurvation, in the case of thicker ones by welding.

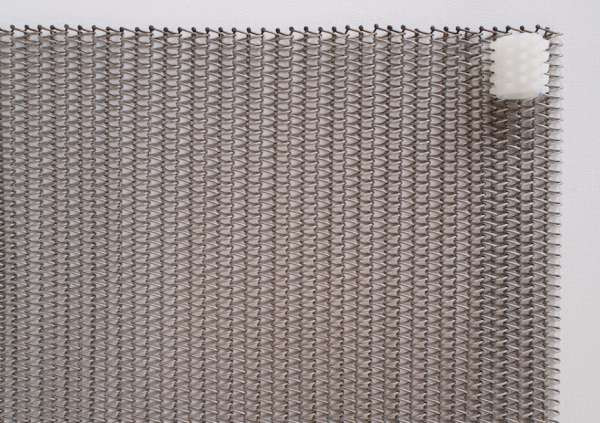

Use

It is used as a cooling belt in the confectionery and chocolate industry, as a conveyor belt in the chemical industry, as a cooling belt for rubber and plastic products, for glass products and hot castings etc.